Today I interviewed the OBS group from the Institute of Geophysics and Planetary Physics (IGPP) at the Scripps Institution of Oceanography, which is part of the University of California San Diego. Scripps has a long history of making OBSs. In the early 1990’s, I was a postdoctoral fellow at IGPP and at that time there were three OBS groups at Scripps.

With early Scripps instruments (e.g. the OBS88), the OBS package was housed in a giant sphere mounted on a tripod. In the 90’s, a decision was made to modularise the instruments, separating the sensor from the recording unit and moving various components into aluminium-alloy tubes. The so-called ‘L-Cheapo’ carried a short-period sensor, and from 2000 onward the equipment was incrementally upgraded to broad band sensors. The instruments we are using deploy a Nanometrics Trillium 240.

The Scripps group is led by Jeff Babcock and is part of John Orcutt’s research group. Scripps is part of the USA ocean bottom seismometer instrument pool, or OBSIP, which also includes instruments from the Lamont Doherty Earth Observatory and the Woods Hole Oceanographic Institute. An advantage of OBSIP is that it has led to common data formats.

The Scripps group is led by Jeff Babcock and is part of John Orcutt’s research group. Scripps is part of the USA ocean bottom seismometer instrument pool, or OBSIP, which also includes instruments from the Lamont Doherty Earth Observatory and the Woods Hole Oceanographic Institute. An advantage of OBSIP is that it has led to common data formats.

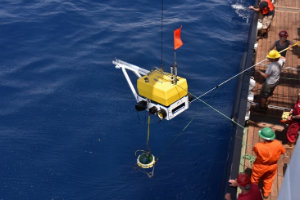

The Scripps instruments are a bit different from the LDEO and IPGP instruments in that they use syntactic foam for buoyancy. The foam is made from microscopic air-filled beads set in an epoxy matrix. The Scripps engineers have adopted a moulding technology that helps to make the instrument more streamlined and reduces the manufacturing cost. The bright-yellow foam is rated to depths of 6000m and rises at a much faster rate (50m/minute) than that of an OBS using spheres. The foam is slightly heavier than the glass spheres and is more expensive, but is more durable and has a longer life span. At 500 kg, the Scripps OBS is ~100 kg heavier than the other OBSs on the ship.

Otherwise, the Scripps instrument has very similar components to the other instruments. The clocks, acoustics, and memory storage are the same, and, as with the other groups, they have developed their own data logger. The anchor is a large metal platform, released by a spring and burnwire assembly. Their instruments draw 800 mWatts and are powered by 132 DD-cell lithium batteries, which have a mass of 50 kgs. Power for the strobe light, radio frequency modem and acoustics comes from ordinary alkaline batteries. They can operate for up to 14 months and 6000 m deep. Here is a picture of the OBS lab on the ship and a picture of Martin and Sean, the Scripps engineers, astride their OBSs on the aft deck.

Otherwise, the Scripps instrument has very similar components to the other instruments. The clocks, acoustics, and memory storage are the same, and, as with the other groups, they have developed their own data logger. The anchor is a large metal platform, released by a spring and burnwire assembly. Their instruments draw 800 mWatts and are powered by 132 DD-cell lithium batteries, which have a mass of 50 kgs. Power for the strobe light, radio frequency modem and acoustics comes from ordinary alkaline batteries. They can operate for up to 14 months and 6000 m deep. Here is a picture of the OBS lab on the ship and a picture of Martin and Sean, the Scripps engineers, astride their OBSs on the aft deck.

As with the other groups, Scripps is continually looking to improve their instruments. The new ‘Abilone’ has a hydrodynamic shield over the Trillium sensor, which should reduce noise by minimising its profile on the seafloor.

As with the other groups, Scripps is continually looking to improve their instruments. The new ‘Abilone’ has a hydrodynamic shield over the Trillium sensor, which should reduce noise by minimising its profile on the seafloor.

Another aspiration is real-time monitoring, especially as we move to more permanent ocean bottom observatories. The limitations of acoustic communication in water make it difficult to transmit data with a high sample rate. Scripps has been experimenting with using autonomous gliders to relay data back to the shore, a ship, or satellites.

I asked each of the instruments groups what are the biggest challenges they face. As we noticed first hand, inconsistencies with the hull transducers on ships can be a real headache. We ended up circumventing the ship’s internal wiring to get a good signal. The same problem was even worse on the deployment cruise on a different ship. Keeping anything at a depth of over 4000m for a year is a challenge. The syntactic foam is more reliable and lower maintenance than glass spheres, but more expensive. Electronics, cables and connectors will continue to improve. We saw an imploded battery connector and evidence of leaks in a few instruments. Funding constraints in general are a common theme and mean that staffing can be an issue with equipment facilities. This cruise has presented a nice opportunity for 4 different research groups to work together and compare notes. I have been impressed with the hard work and dedication of the engineers working in all 4 groups – and how collegial everyone is.